GC fully automatic special gas cabinet

Specification: Fully automatic, automatic switching, automatic blowing.

Standard equipment: automatic switching, explosion-proof and anti-corrosion cabinet

External blowing: PN2, 1/4MVCR interface.

Explosion proof self-locking door, explosion-proof glass observation window, leakage alarm

Vacuum pumping: GN2, 1/4MVCR interface.

Remote cut-off, undervoltage alarm, main material SS316L.

Pneumatic diaphragm valve: 1/4 card sleeve interface.

Operation interface: PLC control, 10 inch color touch screen.

VENT emptying pipe: 1/2MCCR interface.

Optional: Process gas overpressure alarm, panel heating and temperature control device

Vacuum generator, high and low pressure evacuation.

Alarm signal, mobile SMS and phone notification.

Disk specification: 1/4 disk.

GC fully automatic special gas cabinet

Specification: Fully automatic, automatic switching, automatic blowing.

Standard equipment: automatic switching, explosion-proof and anti-corrosion cabinet

External blowing: PN2, 1/4MVCR interface.

Explosion proof self-locking door, explosion-proof glass observation window, leakage alarm

Vacuum pumping: GN2, 1/4MVCR interface.

Remote cut-off, undervoltage alarm, main material SS316L.

Pneumatic diaphragm valve: 1/4 card sleeve interface.

Operation interface: PLC control, 10 inch color touch screen.

VENT emptying pipe: 1/2MCCR interface.

Optional: Process gas overpressure alarm, panel heating and temperature control device

Vacuum generator, high and low pressure evacuation.

Alarm signal, mobile SMS and phone notification.

Disk specification: 1/4 disk.

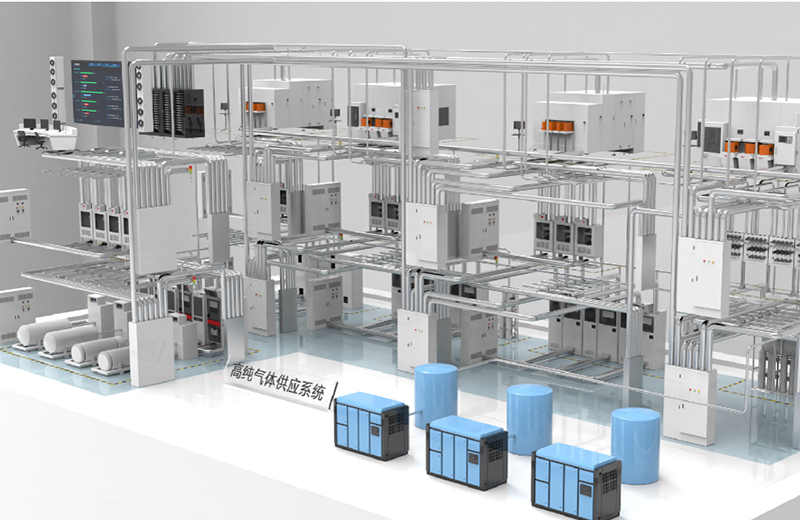

High flow special gas conveying equipment (BSGS)

Control cabinet power supply: control source 220VAC, 50HZ, 500V; Panel power supply 220VAC, 50HZ, 1KV/;

Vacuum pumping: GN2, V4MCCR interface

VENT exhaust pipe: 1/Z MVR connected to C

Standard configuration: automatic switching, automatic blowing, explosion-proof and anti magic cabinet. Anti scenic self-locking door, explosion-proof glass observation

VMP valve distribution disc

The panel style overall structure is easy to install.

The main material is made of SS316L stainless steel, which is more suitable for laboratory special gas.

Metal diaphragm pressure reducing structure.

Hard sealed structure to avoid material aging and pollution.

Adapt to non hazardous gases.

Adopting diaphragm valve control, simple flow channel, reliable operation, and long service life.

The pressure reducing valve and pipeline have undergone pressure and leakage tests.

All diaphragm valve knobs are equipped with opening and closing indicator windows.